Recent Projects

| A Design and manufacture of the AD33510-4 Synchrophaser Test Set for the 761230-1/-2, 766840, 774800 Synchrophaser units originally manufactured by Hamilton Standard. |

| • |

| Honeywell BACKLIGHT CCA 4091889-1001 Tester. |

| • |

| Thales TCAS Vertical Speed Indictor Test Set for 457400 Series Indicators. |

| • |

| Honeywell TCAS Vertical Speed Indicator Test Set for the IVA-81A/81D Indicators |

| • |

| Developed repair capabilities for circuit cards in Honeywell MFD 8001671-902. |

| • |

| Developed repair capabilities for Howell JetCal Analyzer BH112JD-80 |

Key personnel: Thomas M. Woscek

Background: 40 years in the avionics repair and overhaul business. Started working at Airesearch Aviation at the Los Angeles Airport as an avionics technician in 1979 after completing 4 years in the US Marine Corps.

Started FAA certified avionics repair station in 1985. Specialized in aviation radar repairs such as the APN-59 system on the C-130. This repair station was purchased in 2012.

Started new business: TMW Enterprises in 2013 designing and manufacturing specialized avionics test equipment. Acquired specialized skills in printed circuit board design and layout to complement this new business. Received FAA re-certification in 2019.

Past Projects

| APQ-153/APQ-159 Fire Control Radar Antenna, Rcvr-Xmtr, Control Test Set 633175-303. | Sony Trans Com Cabin Entertainment systems tester 980-7072-001. |

| • | • |

| APN-59 Radar System test panel. | Servo Tester for Bendix/King KS-270/270A and KS372 series autopilot servos. |

| • | • |

| APN-171 Radar Altimeter system test panel. | Cessna Standby Battery Test Box 7088020-1. |

| • | • |

| Collins 514M-2 Interface Panel to 972V-1 Test Set for the 374D-3 TACAN Rcvr-Xmtr. | 329B-8J/Y Flight Director Indicator Tester. |

| • | • |

| Radar Altimeter Test Set T322967 for testing the RT-220 and RT-300 Radar Altimeters. | Generator Control Unit 976J902-2 Tester. |

| • | • |

| Avtech TR5171-1 Test Set for testing the Avtech 5171-1 audio panels used in the SAAB 340. | IVA-81A Output Dimmer Module 30090003-05XX Tester. |

| • | • |

| Audio Panel TS502-0108 Test Set for testing the Telephonics 502-0011 audio panel in the SAAB 340. | IVA-81A Power Supply 30090002-05XX Tester. |

70 HZ VCO CARD AD33510-4 Test Set

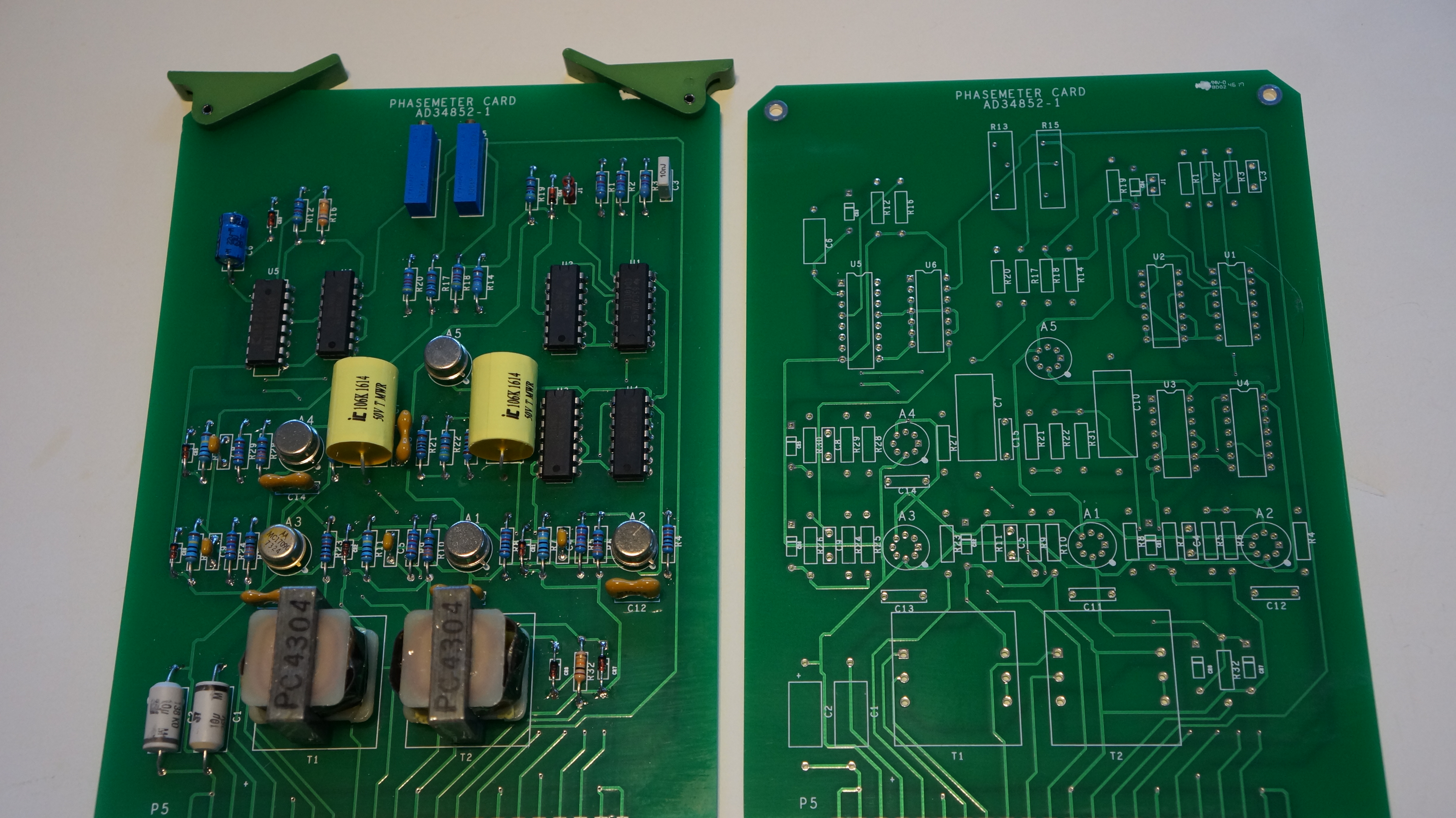

Phasemeter Card AD33510-4 Test Set

Power Interrupt Card AD33510-4 Test Set

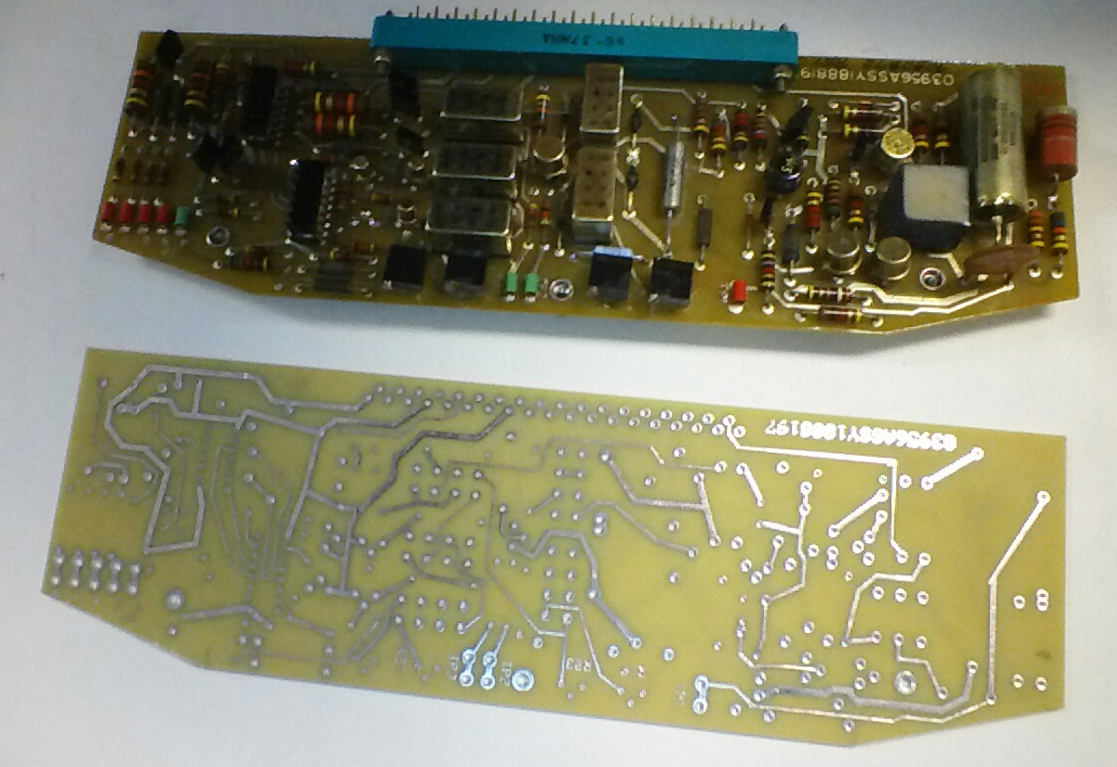

PRF Generator Circuit Board 1888197

A3101 Board Assembly 4007559-0501 Circuit Board

A3202 Board Assembly 4007599-0501 Circuit Board