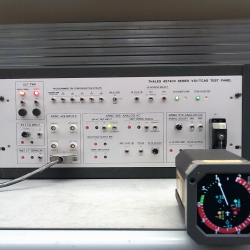

• SYNCHROPHASER TEST SET AD33510-4 equivalent

• For 54H60 SYNCHROPHASER on C-130 Hercules, P-3C Orion Aircraft

• Part Numbers 761230-1/-2, 766840-1, 774800-1, 768950-5, 773170-3

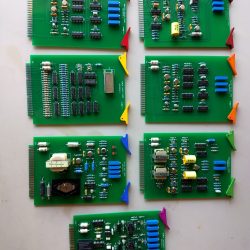

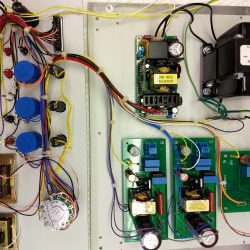

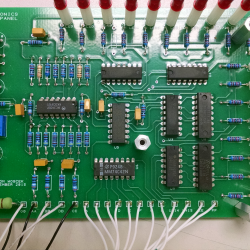

This is the most recent design and was a major project. It is based on the AD33510-4 test set originally manufactured by Hamilton Standard. My design has many improvements from the original AD33510-4 test set. It simulates the signals from the propellers, throttle control (power level position), engine rpm (tachometer). Checks master engine operation from engine 2 or 3 and engines 1, 2, 3, or 4 as a slave engine. Checks underspeed and overspeed conditions. Fuel Governor, Speed, and Throttle tests are checked. Power Interrupt tests along with the NORM/GOV and SYNC tests are accomplished. Repairs and overhauls of the C-130/P-3 Synchrophasers can be accomplished by testing and aligning the four Power Amplifiers circuit cards, Master Sync circuit card, and Double Slave circuit card. The test set includes the Speed Bias Servo assembly housed on the bell housing of the T56 engine. The Speed Bias Servo receives the output signals from either of the four power amplifier circuit boards and the motor moves in response to the outputs. The DC Voltmeter monitors the voltage outputs in accordance with rotary switch S3 selection. It has the Power Authority and Master RPM Trim test capabilities which are specific to the 768950-5/773170-3 Synchrophasers on the P-3 Orion. This test set has a total of thirteen printed circuit boards. The last photo shows the seven printed circuit boards that are accessible from the top of the test set. The unit is housed in a fiberglass case with easily transported handles and wheels. The power requirements are 115VAC 400HZ single phase.

The 766840-1, -2 and the 774800-1 Synchrophaser and Adapter assemblies replaced the 588584 tube-type Synchrophaser on the C-130 Hercules aircraft. The 773170-3 Synchrophaser and Adapter assembly replaced the 585500 tube-type Synchrophaser on the P-3 Orion aircraft.